Added value

All these aspects result in extremely low operating costs.

Operator friendly

Operator friendly

Excellent accuracy and weight control

Excellent accuracy and weight control

Flour consumption reduced to a minimum

Flour consumption reduced to a minimum

Wide variety of products

Wide variety of products

Highest product quality

Highest product quality

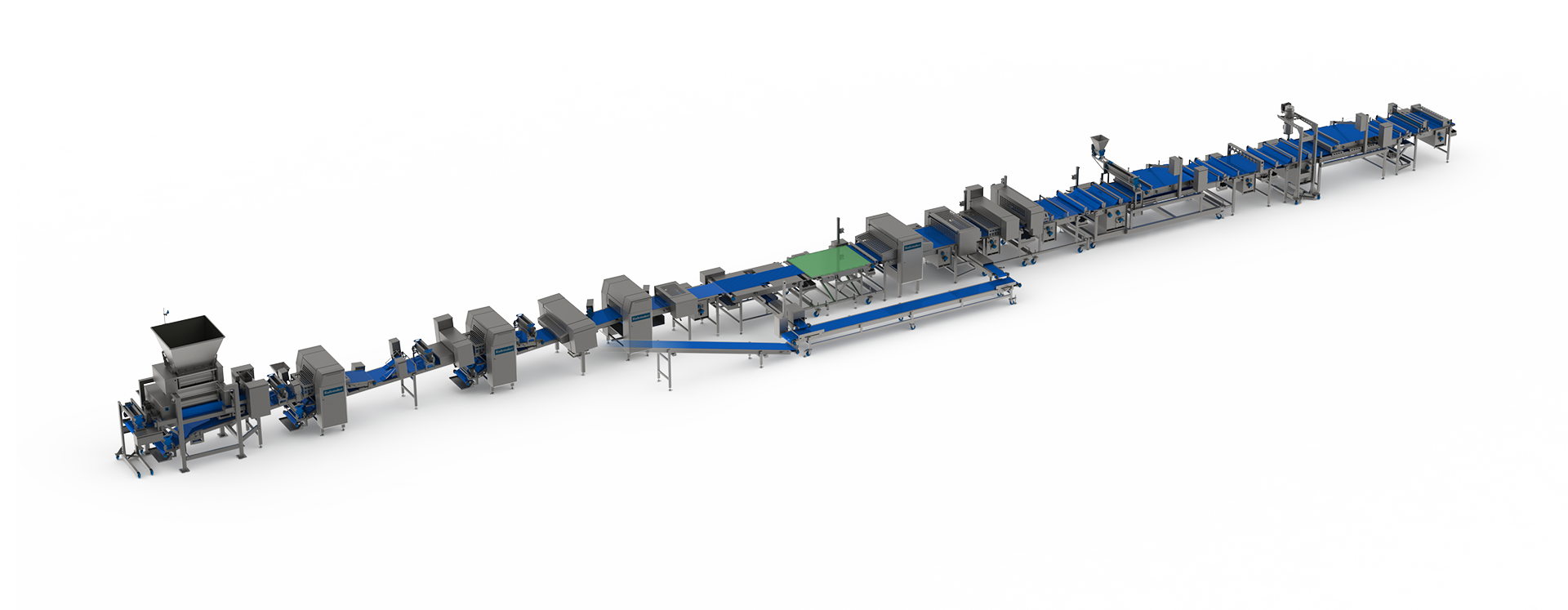

The Rademaker industrial Bread production line is designed for medium to large scale industrial bread manufacturers. From tin breads to high water absorption artisan breads and from pre-fermented to 'green' doughs. Flexibility and fast production changeovers are guaranteed thanks to the unique modular design and the various mobile units. Compared to dedicated industrial bread lines, this results in a shorter Return On Investment, that makes the Bread production line the most desired industrial bakery line in the market. The Bread production line is developed to produce a wide variety of bread products for a medium scale bakery to any industrial bakery. Capacities ranging from 500 to 9,000 kg per hour, consistently produced hour by hour, day by day, and year by year.

WORKING WIDTHS

600 mm | 800 mm | 1,000 mm | 1,200 mm

PRODUCTS

Sweet fingers - milk roll

Sweet fingers - milk roll

Focaccia

Focaccia

French bread

French bread

Sandwiches Baguette sandwiches

Sandwiches Baguette sandwiches

Petit Pain

Petit Pain

Gluten free

Gluten free

Freeform bread

Freeform bread

Pavé

Pavé

Baguette au Kilometre (sliced or rolled)

Baguette au Kilometre (sliced or rolled)

Rolled loaves

Rolled loaves

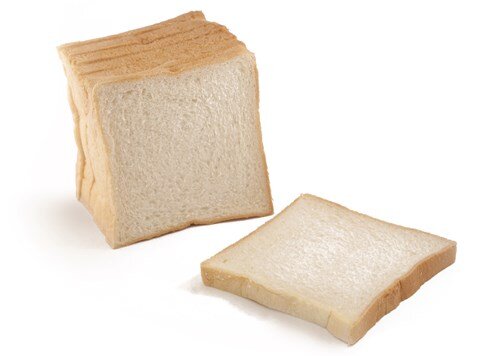

Toastbrot (Typ asiatisch und englisch)

Toastbrot (Typ asiatisch und englisch)

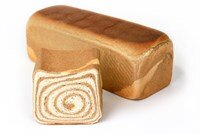

Two-coloured bread

Two-coloured bread

Round bread

Round bread

Pointed baguette

Pointed baguette

Ciabatta

Ciabatta

Baguette (sliced or rolled)

Baguette (sliced or rolled)

PRODUCING THE VARIETY OF YOUR CHOICE

Versatility is key in our Bread line. Thanks to the modular set-up, this flexible production line allows you to produce a wide range of breads by simply exchanging one or more modules. A good recipe is the key to your bread quality. As it is our quest to produce a wide variety of high quality breads, the Bread line is capable of handling a large variety of recipes, including those for breads with a high water percentage (strongly hydrated) or low salt content, with bio ingredients, gluten free, pre-fermented, Levain, mother dough, biga and sponge dough. All these recipes result in a very wide range of bread products. If you want to produce tin breads at your bakery we focus on achieving a fine and consistent crumb structure, as with the high-water absorption artisan breads we focus on obtaining a light, authentic and open bread structure.

That’s why we developed the DSS pre-sheeter, it’s able to process these doughs without any problems. The double chunking principle makes it able to maintain the dough characteristics after the mixing and proofing process. Furthermore it will avoid any stress during the sheeting process. Whatever bread product you desire to produce, our dough processing capabilities are second to none. While our Bread line is developed to produce an extensive and international assortment of breads, we can take the extra step and apply one of the major strengths of Rademaker, namely developing customized modules tailored to your specific needs.

OVERVIEW OF THE MOST IMPORTANT BREAD SHAPING METHODS:

Cut breads

After sheeting, the dough is shaped in rows by rotating knives or guillotine. The result is a wide variety of breads, that include; ciabatta, triangles, square buns, hexagonal, cut baguettes, cut petit pain and bara rustika, flatbreads, pita and pizza.

Rolled breads

After sheeting, the dough is cut using the guillotine. Next, Rademaker's moulding technology is applied to roll and shape the dough. Rolled baguettes, rolled petit pain and bara rustika, free standing bread, tin bread, toast bread (open & closed top, 4 pieces), brioche and rolls are te result of this method.

Rounded breads

After sheeting, the dough is cut and rounded using the Rademaker rounding unit, resulting in traditional breads such as boule, rolls, ssandwich rolls and hamburger buns.

Tin breads

Cut and rolled dough pieces can be placed into baking tins. The final products of this process include tin bread and toast bread (open top, closed top, 4 pieces and multi-pieces) and typical English sandwich bread.

KEY ADVANTAGES OF OUR BREAD PRODUCTION LINE

• Ensuring the highest product quality due to unique Low Stress processing and make-up sections

• Excellent weight control

• Designed according tot the highest hygiene levels

• Absolute minimum usage of flour

• User-friendly PLC line control with recipe managment and automatic speed & height adjustment

TECHNICAL ANALYSIS & COST OF OWNERSHIP

Thorough tests in the Rademaker Technology Center (RTC) are performed in order to determine the exact positive effects of the improved dough homogeneity on the final product weight accuracy. Subsequently the resulting benefits for the Cost Of Ownership are assessed by details calculations based on actual (plant) bakery circumstances. Read more..

GET IN TOUCH WITH US

At Rademaker we can deliver different types of bakery production solutions for your specific needs. We are excited to be of value for you!

Are you interested in our Bread line? Feel free to contact our sales team through +31 (0)345 543 543, send an email to sales@rademaker.nl or fill out our contact form.

We are happy in welcoming you to a partnership finding the best solution for your bakery!