Perfection in the production of Pie’s, Egg tarts, Pastel de Nata and quiches

Pressing line

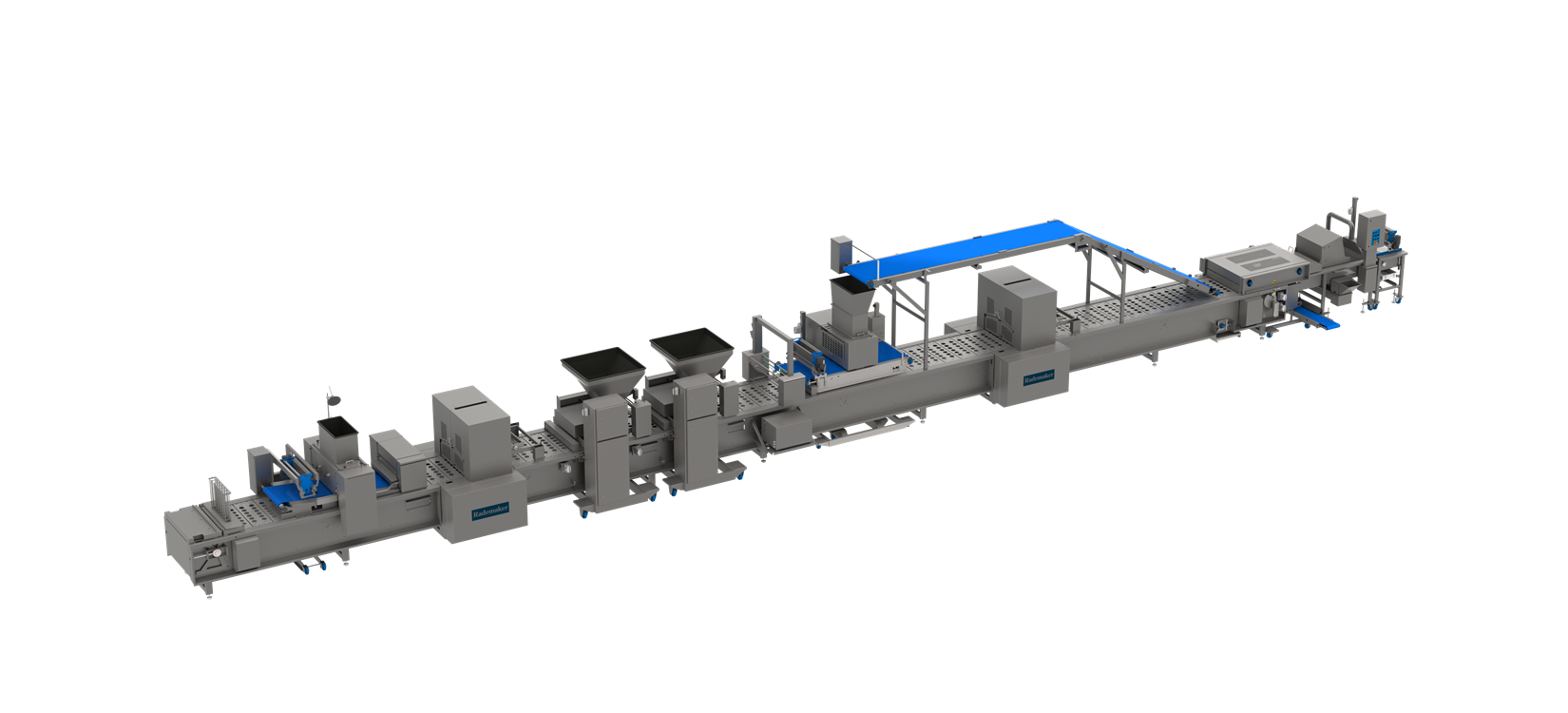

Pies, Pastel de Nata, and Quiches Line

Rademaker manufactures production lines for pies, quiches, and pastel de nata / egg tarts for a wide range of customers worldwide. Our production lines are built from modules with proven technical concepts and are known for the excellent product quality, starting with the precise positioning of the dough pieces. Additionally, the servo-driven press is equipped with a unique compensation mechanism that ensures perfect dough shaping with minimal waste. This is achieved by automatically adjusting the bottom thickness to the fluctuating weight of the dough pieces. Finally, the control system can be easily set to the desired number of strokes, while the system itself takes care of the overall setting adjustments.

Our Pie & Quiche Selection

This overview highlights the variety we offer. And there’s even more we can create together

-

Savory pies

-

Sweet pies

-

Egg tart / Pastel de nata

-

Quiches

Pastel de nata

Quiche lorain

Quiche spinache

Mini quiches

CAPACITY

The production capacity varies depending on size, dough type, and filling, ranging from 5,200 pieces per hour (product diameter 250 mm) to 20,000 pieces per hour (product diameter 80 mm). A capacity of up to 40,000 pieces per hour can be achieved in a tandem configuration. Production is possible in aluminum foil, paper trays, metal baking sheets, profiled baking sheets, and pre-formed baking trays. Product diameters range from 50 to 282 mm.

KEY ADVANTAGES

- Product quality, efficiency, and flexibility

- Fast changeover times

- Tailored layout solutions

- Hygienic design

- Low ownership costs

ADDED VALUES

Quick and easy changeover and cleaning

Tailor-made layout solutions

Low operating costs

explore a world of Product options

Our Pressing Line

For more information download the brochure, request a quote or get in touch with your regional sales agent.

Rademaker pressing Line

- Handles from 500 up to 14,000 kg of dough per hour

- Products from 50 up to 282 mm in width

- 600 mm | 800 mm | 1.000 mm | 1.200 mm

Contact Us

Ready to automate your production? Learn more and get in touch by phone, email, or by using our contact form

At Rademaker, we support your production around the clock. 24 hours a day, 365 days a year.

Crafting the perfect product involves many different techniques. That’s why your chosen production process is our top priority. Our commitment goes far beyond equipment delivery and installation. We offer a full range of services to cover all system- and process-related issues throughou the entire operational life of your machinery, as well as support in training, development and testing

SERVICES & Support

OPTIMIZING YOUR PRODUCTION IS

OUR PRIORITY

RTC

Rademaker Technology Centre

Upgrades & Optimizing

Customer Training

Rademaker Academy

Consultancy

Spare Parts

Helpdesk

System integration

At the Rademaker Technology Centre (RTC), your product ideas come to life. This is where innovative concepts are developed and tested, and where they evolve into fully operational Rademaker production lines.

Boost your line’s performance and extend its lifespan with our system upgrades. We replace outdated components with the latest technologies and test everything with your products. This ensures your equipment stays reliable and future-proof.

Boost skills and knowledge with training from the Rademaker Academy. We help your team operate and maintain equipment more effectively

Are you looking to improve production efficiency, solve product challenges, or develop new bakery concepts? Our consultants work side by side with your team to achieve the best possible results.

Ensure consistent performance with high-quality spare parts from Rademaker. Our service packages reduce downtime and support efficient, reliable production. We help you select the right parts based on your daily needs and system requirements.

Service Helpdesk 24/7 for telephone or on-site support and remote diagnostics

Discover how Rademaker connects technology and expertise to create seamless, fully integrated bakery production lines that maximize efficiency and performance