Cost of ownership

TECHNICAL ANALYSIS ASSESSMENT OF COO

The Rademaker industrial bread production line is based on sheeting technology. Sheeting technology is preferred over traditional bread production systems because sheeting offers several key advantages. First, sheeting makes it possible to process a wide variety of dough types, from 'green' to pre-fermented dough, all at high capacity. By using tension-free dough formation and laminating technology, you can basically achieve any desired dough and bread structure. The dough structure created during mixing, kneading and preforming remains intact, resulting in products of the highest quality.

Moreover, the line consists of a number of innovative and versatile modules on wheels that can easily be placed in any desired line sequence. This flexibility is essential when it comes to configuring your application and managing production efficiency.

Our bread line is suitable for processing a wide range of dough types on an industrial scale from about 500 to 9,000 kilograms per hour (batch sizes ranging from 200 - 700 kg/litre).

The main advantages of this unit have already been demonstrated with several customers: the Rademaker bread line has proven to be extremely dough-friendly for a wide range of products and dough types. Even the most delicate dough structure remains intact during the slicing and pre-sheeting process. Moreover, the line is easy to operate and its accessibility allows quick and easy cleaning procedures.

Besides these important advantages, our bread line also ensures a very stable product flow. This is a direct result of the efficient splitting of the cascade breading process and the subsequent sheeting operations, which are perfectly controlled by various sensors. Actual results in the factory environment show that this stable product flow produces the best possible dough homogeneity.

TEST STAND

Thorough testing at the Rademaker Technology Centre (RTC) is carried out to determine the exact positive effects of improved dough homogeneity on final product weight accuracy. The resulting benefits to Cost Of Ownership are then assessed through detailed calculations based on actual plant conditions. Several tests were carried out with both the Rademaker industrial bread line and comparisons with state-of-the-art competing lines and systems and previous-generation Rademaker equipment. A wide range of different dough types were tested with water percentages ranging from 55% to 85%.

Three different products were selected for high-volume testing: 80g square buns, 165g baguettes and 150g ciabatta. Several runs with significant numbers of products were carried out to ensure statistically correct results. During these detailed and thorough tests, the volume and cell structure of the final products and the accuracy of the weight before and after the baking process are examined.

Summary of results

Comparison of volume, homogeneity and final accuracy was carried out for the above product type in different runs. Different environmental conditions were also assessed to achieve the most reliable result.

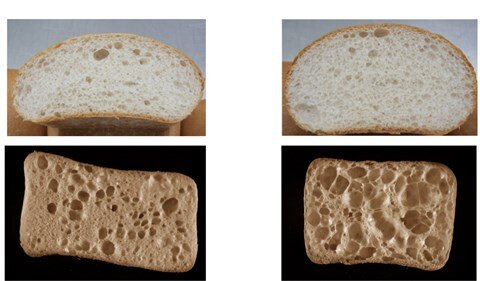

Furthermore, the volume and cell structure are shown in the images.These pictures clearly show that the structure of the dough remains completely intact due to the very dough-friendly treatment of the Rademaker Crusto bread line.

Interested in the Rademaker industrial bread production line? Please contact our sales team: +31 (0)345 543 543 or by e-mail: sales@rademaker.nl.